LAMINATOR

Manual Laminator

SKY Lam 380 Super Dual

Features

- Chrome Roller

- Anti Curl Control Set

- Safety Guard

- Auto Power Off

End cutter, air cooling fan, emergency stop switch and safety guard are installed basically.

(*Option : Stand)

Micom System (Auto Power Off function and Memory function etc.)

- Max. Laminating Width : 350 mm (13.8″)

- Max. Laminating Speed : 4.6 m/min

- Max. Laminating Thickness : 13 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 4

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Display : LCD

- Preheating Time : 8 min.

- Power Supply : AC 100, 110, 120, 230, 24OV (50/60Hz)

- Power Consumption : 1,550 watts

- Dimension : 700 x 460 x 272 mm

- Weight : 55 kg

- Operation Temperature : 0 -150℃

SKY Lam 720 Super Dual

Features

- Chrome Roller

- Anti Curl Control Set

- Safety Guard

- Auto Power Off

End cutter, air cooling fan, emergency stop switch and safety guard are installed basically.

(*Option : Stand)

Micom System (Auto Power Off function and Memory function etc.)

- Max. Laminating Width : 680 mm (26.8″)

- Max. Laminating Speed : 3.6 m/min

- Max. Laminating Thickness : 13 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 4

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Display : LCD

- Preheating Time : 8 min.

- Power Supply : AC 100, 110, 120, 230, 24OV (50/60Hz)

- Power Consumption : 1,550 watts

- Dimension : 1,040 x 460 x 272 mm

- Weight : 80 kg

- Operation Temperature : 0 -150℃

SKY Lam 1200

Features

- Hot & Cold Digital Roll Laminator

- Safety Guard – Rollers shall be stoped automatically if will be opened.

- Special Core – 3 sizes(25, 58 and 76mm) in one unit.

- Auto Power Off – If this roll laminator will not be used for more than 2 hours continuously, its power can be automatically off.

- LCD Display

- Emergency Stop

- Side Cutters

- Air Cooling Fans

- Foot Switch

- Max. Laminating Width : 1,200 mm (47.2″)

- Max. Laminating Speed : 3.3 m/min

- Max. Laminating Thickness : 13 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 4

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Display : Dual LCD

- Preheating Time : 10 min.

- Power Supply : AC 200 ~ 24OV (50/60Hz)

- Power Consumption : 1,800 watts

- Dimension : 1,490 x 460 x 274 mm

- Weight : 115 kg

- Operation Temperature : 0 -150℃

SKY Lam 1650

Features

- Hot & Cold Digital Roll Laminator

- Safety Guard – Rollers shall be stoped automatically if will be opened.

- Special Core – 3 sizes(25, 58 and 76mm) in one unit.

- Auto Power Off

- 2 LCD Display

- Emergency Stop

- Side Cutters

- Air Cooling Fans

- Foot Switch

- Max. Laminating Width : 1,630 mm (64.5″)

- Max. Laminating Speed : 3 m/min

- Max. Laminating Thickness : 13 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 4

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Display : LCD

- Preheating Time : 35 min.

- Power Supply : AC 200 ~ 24OV (50/60Hz)

- Power Consumption : 3,100 watts

- Dimension : 1,940 x 540 x 350 mm

- Weight : 160 kg

- Operation Temperature : 0 -150℃

LM-360N Roll Laminator

The machine can do cold and hot lamination.

- Paper Width : 340mm

- Paper Thickness : 5mm

- Core Size : 1″ & 3″

- Speed : 2m / min adjustable

- Temperature : 0-160 degrees

- Consumption : 650W

- Dimensions : 620 x 520 x 310mm

LM-480N Roll Laminator

The machine can do cold and hot lamination.

- Paper Width : 480mm

- Paper Thickness : 5mm

- Core Size : 1″ & 3″

- Speed : 2m / min adjustable

- Temperature : 0-160 degrees

- Consumption : 900W

- Dimensions : 760 x 420 x 310mm

Semi Automatic Laminator

FOLIANT Gemini 400 NG-S

The FOLIANT Gemini 400 NG-S is a semiautomatic high pressure laminating machine (laminator and separator) developed for a digital printing machines outputs lamination. The machine is equipped with a pneumatic pressure system of laminating rollers with an easy thrust control. A small compressor is integrated inside the machine frame. The machine has been designed with an operating width of 380 mm and it represents an ideal choice for professional single side lamination in digital shops and all other printing shops, printing and processing sheets up to B3+ size (the largest format is 38 x 58 cm, with a special option even 38 x 66 cm). Maximum speed is up to 15 meters/min.

The machine’s main feature is a pneumatic pressure system in a heavy duty mechanism enabling to achieve a very high working pressure, one single phase 220 – 240 V supply cable, a small integrated compressor inside the machine frame (i.e. no external source of pressured air is required), a nice design and an easy machine operation. The machine is supplied with a modular stand covered with a nicely designed side panels as a standard accessory. An RU 400 Reception Unit and/or a Jogger 400 for storing the laminated sheets can be supplied as an option. The machine requires a minimum floor space of 74 x 220 cm including the Jogger.

The FOLIANT Gemini 400 NG-S is a semiautomatic machine. The feeding is manual. The laminating unit is equipped with a synchronized feeding conveyor and an adjustable side guider for an easy manual loading.

The FOLIANT Gemini 400 NG-S laminator maximum sheet size is 38 x 58 cm. The option allows laminating sheets of maximum size 38 x 66 cm. The minimum sheet size is 20 x 30 cm (A4).

The roll of a film is mounted on an easy handle shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is done between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with an infra-red heating spiral, with a sensitive contact temperature sensor. The pressure is pneumatically adjustable to achieve an extra high pressure between the laminating rollers. A small compressor is integrated inside the machine frame.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent scratches on sheets printed on both sides by digital print with sensitive inks).

The belt separator (sheeter) is equipped with a separating roller and a deflection wheel. The separated sheets are delivered into a reception unit or a vibrating jogger (options).

The machine laminates the BOPP films (23 – 42 microns). The Nylon films (max 35 microns) can be laminated with the optional module integrated inside the machine separator.

FOLIANT Vega 530S

The FOLIANT Vega 530S is a new generation of easy available very compact industrial laminating machines, designed for a heavy duty “In-House” lamination of digital and offset outputs (max. format 53 x 75 cm), in a semiautomatic configuration – manual feeding, automatic separation with a bump separator and adjustable twin decurl bar. Due to its pneumatic high pressure system (with integrated compressor inside machine frame), format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 18 m/min., while performance is limited by the manual feeding only.

The FOLIANT Vega 530S is equipped with an infeed table with synchronized belts and adjustable side guider for manual feeding. Due to upper overlapping, feeding belts and side guide, the manual feeding is easy.

The FOLIANT Vega 530S laminator maximum sheet size is 53 x 75 cm. The minimum sheet size is 20 x 30 cm (A4).The FOLIANT Vega 530S machine is a single sided thermal industrial laminator, laminating the 115 – 500 gsm paper.

The machine does not need any external source of pressured air for the pneumatic pressure system, because the compressor is integrated inside the machine frame as a standard delivery.

The laminating unit is equipped with an adjustable twin decurl unit that can change angle during the operation:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent the scratches on sheets printed on both sides by digital print with sensitive inks).

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 42 microns film. The film holder unit is equipped with an in-line trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The whole machine is controlled with an interactive, easy understandable icon based touch screen and its used control system includes many automation items for an easy control of the machine and a reliable lamination.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine control unit. The separated sheets are delivered into a vibrating jogger (optional) or adjustable reception unit (optional).

The machine laminates the BOPP films (24 – 42 microns). Nylon films (24 – 35 microns) can be processed with optional Pneumatic separation option.

SF-520Z

The hydraulic laminator from Sunfung is a hot laminator and allows the flexibility of single side OPP roll film lamination and encapsulation providing an affordable and effective solution to outsourcing.

Built for continuous use on an everyday basis and constructed using parts of the highest quality only.

The hydraulic laminator has been designed to help breathe life into your business by allowing you to provide your customers with a service you previously had to outsource, enabling you to offer your customers a truly one-stop shop.

- Auto separation feature

- Hydraulic control paper press

- Heavy duty construction

- Fast speed and temperature control

- Non-sticky film roller

- Thermal or Cold laminating

- Steel roller for even heating

- Overlap feed separation

- Higher standard electrical control

- Max film width : 480 mm

- Max speed : 12 m/min

- Paper thickness : 90-600 gsm.

- Core Size : 3″

- Temperature : 20-160 degrees

- Dimensions : 900 x 1600 x 1400mm

- Weight : 380kg

- Power consumption : 4000W

LM-490D

Professional Laminator

The machine can do cold and hot lamination, single side and double side lamination.

Anti-curling device can be manually adjustable.

It has oil in the heating roller to keep the temperature.

- Paper Width : 490mm

- Core Size : 1″ & 3″

- Pressing Type : Pneumatic

- Speed : 0-10m / min adjustable

- Temperature : 80-125 degrees

- Consumption : 3000W

Automatic Laminator

FOLIANT Vega 400A

The FOLIANT Vega 400A is a new generation of easy available very compact industrial laminating machines, designed for a heavy duty digital outputs lamination, with an integrated deep pile vacuum feeder and a high speed bump separator, with non-sticky pressure roller and in-run adjustable twin decurl bar and overlap system. Due to its pneumatic high pressure system (with integrated compressor inside machine frame), format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B3+ lamination too. The machine maximum speed is up to 18 m/min., while performance is over 2000 sheets per hour of B3 portrait (white paper 200 gsm).

The FOLIANT Vega 400A is equipped with a rising pile front separation stream feeder and with a vacuum belt head. The built-in Becker vacuum pump is used for sheets front airing and feeding head vacuum. The overlaps are controlled, in an „in-run“mode. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 28 cm pile of paper.

The FOLIANT Vega 400A laminator maximum sheet size is 38 x 66 cm (which is the maximum outputs format from Xerox iGen4). The minimum sheet size is 20 x 30 cm.The FOLIANT Vega 400A machine is a single sided thermal industrial laminator, laminating the 115 – 500 gsm paper. The machine does not need any external source of pressured air for the pneumatic pressure system, because the compressor is integrated inside the machine frame as a standard delivery.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent scratches on sheets printed on both sides by digital print with sensitive inks).

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 42 microns film. The film holder unit is equipped with an in-line trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller with non-sticky surface. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The whole machine is control with an interactive, easy understandable icon based touch screen and its used control system includes many automation items for an easy control of the machine and a reliable lamination.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine control unit. The separated sheets are delivered into a vibrating jogger (optional) or adjustable reception unit (optional).

The machine laminates the BOPP films (24 – 42 microns). Nylon films (24 – 35 microns) can be laminated with optional Pneumatic separation only.

FOLIANT Vega 530A

The FOLIANT Vega 530A is a new generation of easy available very compact industrial laminating machines, designed for a heavy duty “In-House” lamination of digital and offset outputs (max. format 53 x 75 cm), with an integrated deep pile vacuum feeder and a high speed bump separator, with non-sticky pressure roller, in-run adjustable twin decurl bar and overlap system. Due to its pneumatic high pressure system (with integrated compressor inside machine frame), format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 18 m/min., while performance is over 1500 sheets per hour of B2 portrait or over 3000 sheets B3 landscape (blank paper 200 gsm).

The FOLIANT Vega 530A is equipped with a rising pile front separation stream feeder and with a vacuum belt head. The Becker vacuum pump is used for sheets front airing. The overlaps are controlled, in an „in-run“ mode. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 28 cm pile of paper.

The FOLIANT Vega 530A laminator maximum sheet size is 53 x 75 cm. The minimum sheet size is 20 x 30 cm.The FOLIANT Vega 530A machine is a single sided thermal industrial laminator, laminating the 115 – 500 gsm paper. The machine does not need any external source of pressured air for the pneumatic pressure system, because the compressor is built-in inside the machine frame as a standard delivery.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent scratches on sheets printed on both sides by digital print with sensitive inks).

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a in-line trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller with non-sticky surface. The pressure is pneumatically adjustable. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The whole machine is control with an interactive, easy understandable icon based touch screen and its used control system includes many automation items for an easy control of the machine and a reliable lamination.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine control unit. The separated sheets are delivered into a vibrating jogger (optional) or adjustable reception unit (optional).

The machine laminates the BOPP films (24 – 42 microns) and nylon films (24 – 35 microns).

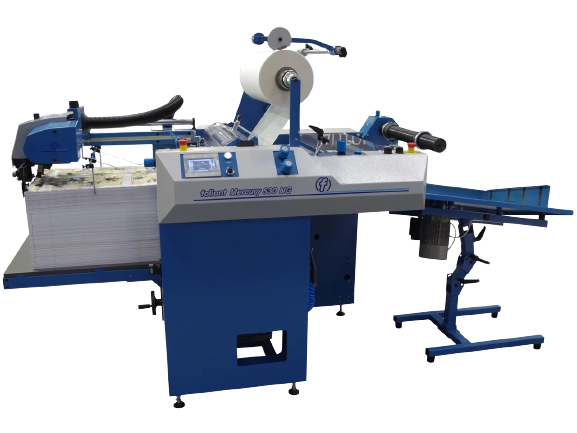

FOLIANT Mercury 530 NG

The FOLIANT Mercury 530 NG is a next generation of popular SF version. It is very compact industrial laminating machine, constructed for a heavy duty digital and offset outputs lamination. It is equipped with suction feeding head Foliant and a high speed bump separator. Several options are available for the Mercury machine – Heidelberg feeding head, Foliant Foiler, non-sticky pressure roller, pallet stacker, etc. Due to its high pressure system, format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 27 m/min., while performance is 2300 sheets per hour of B2 portrait (white paper 200 gsm).

The FOLIANT Mercury 530 NG is equipped with a rising pile back separation stream feeder and with a suction feed head Foliant. It is driven by an Omron servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheets back airing. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 54 cm pile of paper.

The FOLIANT Mercury 530 NG laminator maximum sheet size is 53 x 75 cm. The minimum sheet size is 32 x 25 cm (A4).The FOLIANT Mercury 530 NG machine is a single sided thermal industrial laminator, laminating the 115 – 600 gsm paper.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent the scratches on sheets printed on both sides by digital print with sensitive inks).

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge. The machine is fitted with OMRON Programmable Logic Controllers, which control all machines’ functions. The used PLC system includes many automation items for an easy control of the machine and a reliable lamination. The whole machine is controlled by an interactive easy understandable icon touch screen panel – no language version is needed.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered into a vibrating jogger (optional) or a pallet stacker (optional).

The machine laminates the BOPP films (24 – 42 μm) and Nylon films (24 – 35 μm). The PET films (20 – 26 μm) can be laminated with the optional module only.

FOLIANT Mercury 530NG is certified by independent testing laboratory DGUV Test and obtained GS mark (“Tested Safety”). The measurements for operators safety are better then required by law in order to minimize injuries.

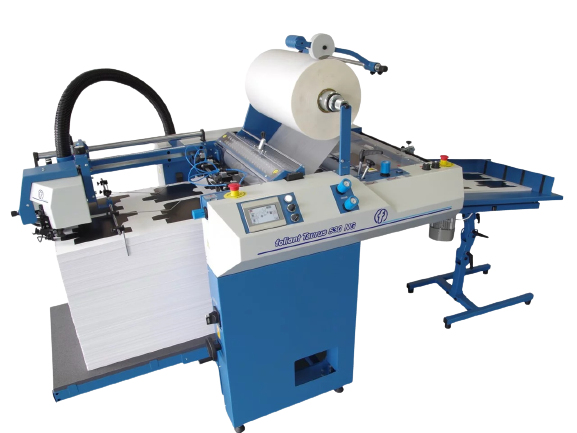

FOLIANT Taurus 530 NG

The FOLIANT Taurus 530 NG is a next generation of popular SF version. It is very compact and fast industrial laminating machine, constructed for non-stop work. It is equipped with a suction feeder, high speed bump separator and many options like non-sticky roller pallet stacker or Foiler. Due to its format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 40 m/min., while performance is up to 3400 sheets per hour of B2 portrait (white paper 200 gsm). It means the performance is 14% higher than its SF predecessor.

The FOLIANT Taurus 530 NG is equipped with a rising pile back separation stream feeder and with a suction feed head. It is driven by an Omron servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheets back airing. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The standard feeder is fitted with a lifting plate and its capacity is a 54 cm pile of paper.

The FOLIANT Taurus 530 NG laminator maximum sheet size is 53 x 75 cm, extendable to 100 cm with optional XL module. The minimum sheet size is 32 x 25 cm (A4).The FOLIANT Taurus 530 NG machine is a single sided thermal industrial laminator, laminating the 115 – 600 gsm paper, with an unique „U“ cross bar for perfect lamination of thin sensitive sheets.

The laminating unit is equipped with twin decurl unit adjustable during run:

- With a decurl blade for strong de-curling effect. The intensity is adjusted by the angle of the blade.

- With a decurl roller for weaker effect. The back print is protected during the de-curling because the paper it not rubbing against the roller but it is rotating together with it.

The roll of a film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller which consists of several rings mounted directly to inner wall of the roller. This ensures that heat transfer is perfect even at maximum speed. A sensitive temperature sensor is also inside the roller as close to surface as possible. The warming up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered into a vibrating jogger (optional) or a pallet stacker (optional).

The machine laminates the BOPP films (24 – 42 μm) and Nylon films (24 – 35 μm). The PET films (20 – 26 μm) can be laminated with the optional module only.

FOLIANT Taurus 530NG is certified by independent testing laboratory DGUV Test and obtained GS mark (“Tested Safety”). The measurements for operators safety are better then required by law in order to minimize injuries.

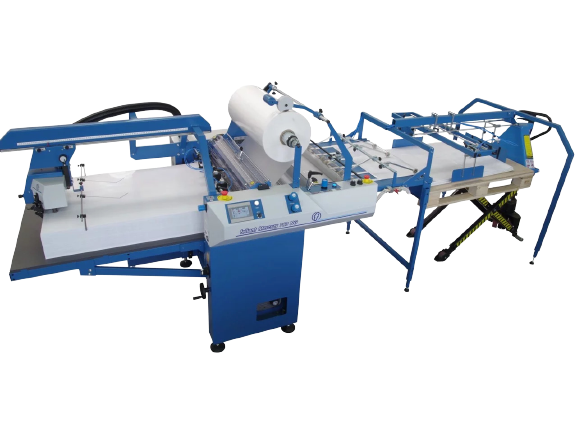

FOLIANT Mercury 760 NG

The FOLIANT Mercury 760 NG is a next generation of popular SF version. This very compact industrial laminating machine is constructed for a heavy duty digital and offset outputs lamination. It is equipped with an integrated suction feeding head Foliant and a high speed bump separator. Several options are available for the Mercury machine – Foliant Foiler, pallet stacker, etc. Due to its high pressure system, format and performance the machine is suitable for all jobs – all kinds of digital printed sheets lamination and high volumes of offset printed sheets size B2+ lamination too. The machine maximum speed is up to 20 m/min while performance is 1300 sheets per hour of B1 portrait (white paper 200 gsm).

The FOLIANT Mercury 760 NG is equipped with a rising pile back separation stream feeder and a suction feed head Foliant. It is driven by an Omron servo motor and controlled by a machine central PLC. The Becker vacuum pump is used for sheets back airing. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The feeder is fitted with a lifting plate and its capacity is a 40 cm pile of paper.

The FOLIANT Mercury 760 NG laminator maximum sheet size is 76 x 110 cm. The minimum sheet size is 32 x 25 cm (A4). The FOLIANT Mercury 760 NG machine is a single sided thermal industrial laminator, laminating the 115 – 600 gsm paper.

The laminating unit is equipped with an adjustable twin decurl unit:

- With a decurl blade for offset printed sheets decurling

- With a decurl roller for digital printed sheets decurling (to prevent the scratches on sheets printed on both sides by digital print with sensitive inks)

The roll of a film is mounted on a quick-changed shaft with a film tension control breaker. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel. The laminating process is made between two laminating rollers – a highly polished chrome roller and a lower hard rubber pressure roller. The laminating roller is heated with a dry electric system inside the roller, with a sensitive temperature sensor. The warming up time is shorter than 10 minutes. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge. The machine is fitted with OMRON Programmable Logic Controllers which control all machine’s functions. The used PLC system includes many automation items for an easy control of the machine and a reliable lamination. The whole machine is controlled by an interactive easy understandable icon touch screen panel – no language version is needed.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered into a vibrating jogger (optional) or a pallet stacker (optional).

The machine laminates the BOPP films (24 – 42 μm) and Nylon films (24 – 35 μm). The PET films (20 – 26 μm) can be laminated with the optional module only.

FOLIANT Mercury 760NG is certified by independent testing laboratory DGUV Test and obtained GS mark (“Tested Safety”). The measurements for operators safety are better then required by law in order to minimize injuries.

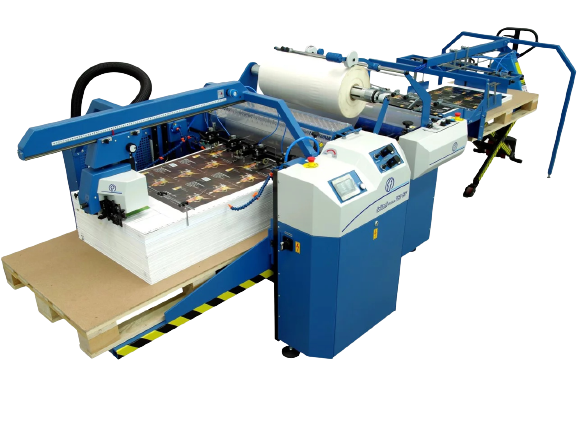

FOLIANT Pollux 760 SF

The FOLIANT Pollux 760 SF is a high speed compact industrial laminating machine, a heavy duty construction machine with a suction feeder and a high speed bump separator, with a walk-in service section and with an optional pallet feeder, a pallet stacker and an electric film loader/manipulator. The machines maximum speed is up to 50 m/min., while the maximum performance is 3000 sheets per hour of a B1 portrait or 6000 sheets per hour of B2 landscape (white paper 200 gsm). The machine requires and external compressor (6 – 8 bar, 150 l / min) as a source of pressured air for its pneumatic systems.

The FOLIANT Pollux 760 SF is equipped with a rising pile back separation stream feeder, with a suction feed head. It is driven by an Omron servo motor and controlled by a machine central PLC. The built-in Becker vacuum pump is used for sheets back and sides airing and feeding head suction cups vacuum. The overlaps are electronically controlled, in an „in-run“ automatic mode, from the touch screen. The accuracy is +/- 2 mm under-lap (in a constant speed). The standard feeder is fitted with a lifting plate and its capacity is a 55 cm pile of paper.

The FOLIANT Pollux 760 SF laminator maximum sheet size is 76 x 110 cm. The minimum sheet size is 32 x 25 cm (A4). FOLIANT Pollux 760 SF machine is a single sided thermal industrial laminator, laminating the paper 115 – 600 gsm, with an unique „U“ cross bar for the thin sheets flat and safety high pressure lamination, mounted in the front of the main laminating rollers, with an „In run“ adjustable de-curl bar.

The roll of a film is mounted on an air shaft that allows very convenient, easy and precise film positioning. The shaft capacity is up to 3000 m of the 24 – 31 microns film. The film holder unit is equipped with a trim slitter and a perforating wheel.

The laminating process is done between two laminating rollers – a highly polished chrome roller, and a lower hard rubber pressure roller. The laminating roller is heated with 6 contact electric heaters inside the roller, with a sensitive in-roll temperature sensor. The pressure is pneumatically adjustable, with an extra independent control knob for each roller edge. The pressure of pulling rollers is controlled with a pneumatic control knob. There is a service „walk-in“ section between the machine laminating rollers and pulling rollers for an easy machine maintenance and rollers cleaning. The machine requires an external source of pressured air 200 l / min, 6 – 8 bars.

The machine is fitted with OMRON Programmable Logic Controllers, which controls all machines’ functions. Used PLC system includes many automatic items for an easy machine control and a reliable lamination. The whole machine is controlled by an interactive easy understandable icon based touch screen – no language mutation is needed.

The integrated bump separator (sheeter) is equipped with a pair of fast cycling rollers. The process is controlled from the machine PLC unit. The separated sheets are delivered through a high speed belt conveyor (for safety loading to the reception unit) into a vibrating jogger (optional) or a pallet stacker (optional).

The machine laminates the BOPP films (23 – 42 microns), Nylon films (max 35 microns) and PET films (max. 25 microns).

SF-390A

Automatic Laminator

SF-390A are compact and environmentally-friendly laminator and foil-flaring devices, designed to offer an in-house decorative effects solution for short-run, on demand digital applications, as well as lamination for traditional lithographic offset output too!

- Auto feeding with air suction

- Pneumatic auto separation

- The anti-curl bar allows thin film laminates to be flat

- Mirror chrome heating roller

- Thermal or Cold laminating

- Touch screen display system

- Digital foiling

- 2 rolls film installation

- Adjustable electric hydraulic pressure system

- Max. size of paper : 390 x 700 mm

- Max speed : 15 m/min

- Paper thickness : 130-400 gsm.

- Core Size : 3″

- Auto feeding : Yes

- Foil feature : Yes

- Temperature : 80-130 degrees

- Dimensions : 1730 x 800 x 1480mm

- Weight : 380kg

- Power : 3.2 kw

SF-540A

Automatic Laminator

It has anti-curl technology to ensure that whatever you laminate comes out smooth and flat. Also it has an automatic feed with auto-overlap. This is the best value single-sided laminator on the market, is simple to use, easy to maintain, quick and reliable.

The automatic feed with auto-overlap makes it easy to feed your work through the laminator and the separator ensures it’s ready for the guillotine the moment it’s been laminated.

Automatic laminators from Sunfung have unique anti-curl technology, in sync with the control panel, ensures that whatever you laminate – a menu, a book cover or a sheet of business cards – comes out flat with no curl or uplift.

- Auto feeding with air suction

- Pneumatic auto separation

- Heavy duty construction

- 20m/min laminating speed

- Mirror chrome heating roller

- Thermal or Cold laminating

- Touch screen display system

- Digital foiling

- Adjustable electric hydraulic pressure system

- Large feeding volume, 2500 sheets, 200gsm paper

- Max. size of paper : 540 x 760 mm

- Max speed : 20 m/min

- Paper thickness : 130-450 gsm.

- Core Size : 3″

- Auto feeding : Yes

- Foil feature : Yes

- Temperature : 20-140 degrees

- Dimensions : 1500 x 1150 x 1350mm

- Weight : 510kg

- Power : 6.5 kw

AUTO-370S

Suction Feeding Laminator

The machine can do cold and hot lamination.

- Laminating Width : 350mm

- Loading Capacity : 130mm

- Pressing Type : Pneumatic

- Core Size : 1″ & 3″

- Speed : 0-10m / min adjustable

- Feeding Type : Suction Feeding

- Temperature : 80-125 degrees

- Overlap Function : Yes

- Dimensions : 1340 x 790 x 1180mm

- Weight : 190kg

Optional : Rewinder for foil sleeking and hot stamping (purchase upon order of the machine)

AUTO-490S

Suction Feeding Laminator

The machine can do cold and hot lamination.

- Laminating Width : 490mm

- Loading Capacity : 130mm

- Pressing Type : Pneumatic

- Core Size : 1″ & 3″

- Speed : 0-10m / min adjustable

- Feeding Type : Suction Feeding

- Temperature : 80-125 degrees

- Overlap Function : Yes

- Dimensions : 1340 x 920 x 1180mm

- Weight : 210kg

Optional : Rewinder for foil sleeking and hot stamping (purchase upon order of the machine)

Pouch Laminator

SKY 325R4

4 Rollers system laminator (A3+)

- Max. Laminating Width : 325 mm (12.8″)

- Max. Laminating Speed : 500 mm/min

- Max. Pouch Thickness : 250 MIC

- Max. Laminating Thickness : 1 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 4

- Display : LCD

- Speed Control : No

- Temperature Control : Yes

- Reverse Switch : Yes

- Preheating Time : 5min.

- Power Supply : AC 100, 110, 120, 230, 24OV (50/60Hz)

- Power Consumption : 550 watts

- Dimension : 480 x 197 x 96 mm

- Weight : 10 kg

- Operation Temperature : 0 -150℃

SKY 325R6

6 Rollers system laminator (A3+)

Features

- LCD Display

- Heat-treatment gears(800℃ or more)

- Special Protection Bar

- Actual Working Time Check Function – Push “MEAS” for 8 sec

- Patent Cooling System

- Max. Laminating Width : 325 mm (12.8″)

- Max. Laminating Speed : 1,350 mm/min

- Max. Pouch Thickness : 350 MIC

- Max. Laminating Thickness : 3 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 6

- Carrier : Free

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Preheating Time : 5 min.

- Power Supply : AC 100, 110, 120, 220, 230, 24OV (50/60Hz)

- Power Consumption : 1,100 watts

- Dimension : 545 x 250 x 125 mm

- Weight : 15 kg

- Operation Temperature : 0 -140℃

SKY 330R10

10 Rollers system laminator (A3+)

Features

- LCD Display

- Strong Roller System

- Heat-treatment gears(800℃ or more)

- Additional outlet rollers

- Special Protection Bar

- Safe System

- Strong Motor System

- Patent Cooling System

- Max. Laminating Width : 330 mm (13″)

- Max. Laminating Speed : 4,000 mm/min

- Max. Pouch Thickness : 350 MIC

- Max. Laminating Thickness : 3 mm

- Heating System : Heating roller internal heater

- Q’ty of Roller : 10

- Carrier : Free

- Temperature Control : Yes

- Speed Control : Yes

- Reverse Switch : Yes

- Preheating Time : 8 min.

- Power Supply : AC 100, 110, 120, 220, 230, 24OV (50/60Hz)

- Power Consumption : 1,300 watts

- Dimension : 536 x 350 x 157 mm

- Weight : 25 kg

- Operation Temperature : 0 -160℃